Zurfafa cikin sarkar samar da kayayyaki, wasu masu sihiri suna juya yashi zuwa cikakkiyar fayafai na siliki na lu'u-lu'u, waɗanda ke da mahimmanci ga dukkan sarkar samar da semiconductor. Sun kasance wani ɓangare na sarkar samar da semiconductor wanda ke ƙara ƙimar "yashi siliki" da kusan sau dubu. Hasken haske da kuke gani a bakin teku shine silicon. Silicon wani hadadden kristal ne mai gagajewa da karfe mai kauri (karfe da kaddarorin da ba na karfe ba). Silicon yana ko'ina.

Silicon shine abu na biyu mafi yawan al'ada a duniya, bayan iskar oxygen, kuma abu na bakwai mafi yawan al'ada a sararin samaniya. Silicon semiconductor ne, ma'ana yana da kayan lantarki tsakanin masu gudanarwa (kamar jan karfe) da insulators (kamar gilashi). Ƙananan adadin ƙwayoyin zarra na ƙasashen waje a cikin tsarin siliki na iya canza halayen sa a zahiri, don haka tsarkin siliki mai darajar siliki dole ne ya yi girma da ban mamaki. Matsakaicin mafi ƙarancin tsarki na silicon-sa siliki shine 99.999999%.

Wannan yana nufin cewa zarra guda ɗaya kawai wanda ba na siliki ba ne ake ba da izini ga kowane atom biliyan goma. Ruwan sha mai kyau yana ba da damar ƙwayoyin ƙwayoyin da ba na ruwa ba miliyan 40, waɗanda sau miliyan 50 ba su da tsabta fiye da silicon-grade.

Masu ƙera wafer ɗin siliki mara kyau dole ne su canza siliki mai tsafta zuwa cikakkun sifofin-crystal guda ɗaya. Ana yin haka ta hanyar gabatar da crystal uwa ɗaya cikin narkakkar siliki a yanayin da ya dace. Yayin da sabbin lu'ulu'u na 'ya'ya suka fara girma a kusa da kristal na uwa, siliki ya fara fitowa a hankali daga narkakkar siliki. Tsarin yana jinkiri kuma yana iya ɗaukar mako guda. Ingot silicon da aka gama yana nauyin kilogiram 100 kuma yana iya yin wafers sama da 3,000.

Ana yanka wafers zuwa ciyayi sirara ta amfani da waya mai kyau na lu'u-lu'u. Madaidaicin kayan aikin yankan silicon yana da girma sosai, kuma dole ne a kula da masu aiki akai-akai, ko kuma za su fara amfani da kayan aikin don yin abubuwan banza ga gashin kansu. Takaitaccen gabatarwar don samar da wafers na siliki an sauƙaƙa sosai kuma baya ba da cikakkiyar gudummawar gudummawar masu hazaka; amma ana fatan samar da tushe don zurfin fahimtar kasuwancin wafer silicon.

Alamar wadata da buƙatu na wafers na silicon

Kasuwar wafer silicon ta mamaye kamfanoni huɗu. Na dogon lokaci, kasuwa ta kasance cikin ma'auni mai sauƙi tsakanin wadata da buƙata.

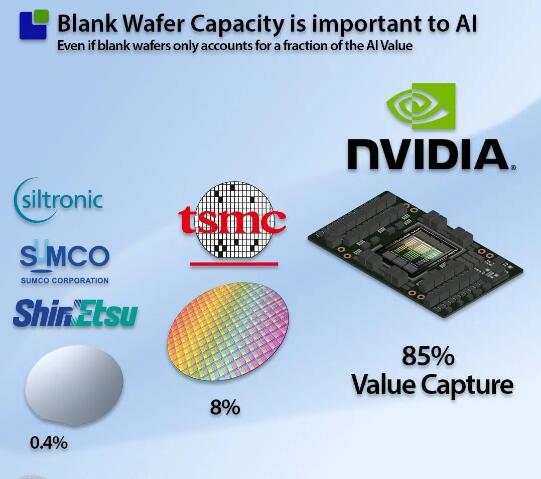

Rushewar tallace-tallace na semiconductor a cikin 2023 ya haifar da kasuwa ta kasance cikin yanayi mai yawa, yana haifar da kayan ciki da na waje na masana'antun guntu su yi girma. Koyaya, wannan yanayin na ɗan lokaci ne kawai. Yayin da kasuwa ke farfadowa, masana'antun za su dawo da sauri zuwa ƙarshen iya aiki kuma dole ne su cika ƙarin buƙatun da juyin juya halin AI ya kawo. Canji daga gine-gine na tushen CPU na al'ada zuwa haɓakar ƙididdigewa zai yi tasiri a kan masana'antar gabaɗaya, kamar yadda Duk da haka, wannan na iya yin tasiri a kan ƙananan ƙima na masana'antar semiconductor.

Rukunin Gudanar da Zane-zane (GPU) gine-gine na buƙatar ƙarin yanki na silicon

Yayin da buƙatun aiki ke ƙaruwa, masana'antun GPU dole ne su shawo kan wasu iyakokin ƙira don cimma babban aiki daga GPUs. Babu shakka, yin guntu ya fi girma ita ce hanya ɗaya don samun babban aiki, saboda electrons ba sa son tafiya mai nisa tsakanin kwakwalwan kwamfuta daban-daban, wanda ke iyakance aiki. Koyaya, akwai iyakance mai amfani don sanya guntu ya fi girma, wanda aka sani da "iyakar retina".

Iyakar lithography tana nufin matsakaicin girman guntu da za a iya fallasa a cikin mataki ɗaya a cikin injin lithography da ake amfani da shi a masana'antar semiconductor. An ƙayyade wannan iyakance ta matsakaicin girman filin maganadisu na kayan aikin lithography, musamman ma'auni ko na'urar daukar hoto da aka yi amfani da ita a cikin tsarin lithography. Don sabuwar fasaha, iyakar abin rufe fuska yawanci yana kusa da murabba'in murabba'in 858. Wannan ƙayyadaddun ƙayyadaddun girman yana da mahimmanci sosai saboda yana ƙayyade iyakar yanki wanda za'a iya tsarawa akan wafer a cikin bayyanar guda ɗaya. Idan wafer ya fi girma fiye da wannan iyaka, za a buƙaci buƙatu da yawa don yin cikakken tsarin wafer, wanda ba shi da amfani don samar da yawan jama'a saboda rikitarwa da ƙalubalen daidaitawa. Sabuwar GB200 za ta shawo kan wannan ƙayyadaddun ta hanyar haɗa nau'ikan guntu guda biyu tare da iyakokin girman barbashi a cikin madaidaicin siliki, ƙirƙirar ƙayyadaddun ƙayyadaddun ƙarancin barbashi wanda ya ninka girma. Sauran iyakokin aiki sune adadin ƙwaƙwalwar ajiya da nisa zuwa wancan ƙwaƙwalwar (watau bandwidth na ƙwaƙwalwar ajiya). Sabbin gine-ginen GPU sun shawo kan wannan matsala ta amfani da ma'aunin ƙwaƙwalwar ajiya mai girma (HBM) wanda aka sanya akan siliki iri ɗaya tare da guntuwar GPU guda biyu. Daga hangen nesa na silicon, matsalar HBM ita ce kowane yanki na silicon ya ninka na DRAM na gargajiya sau biyu saboda babban haɗin kai da ake buƙata don babban bandwidth. HBM kuma yana haɗa guntu mai sarrafa dabaru a cikin kowane tari, yana haɓaka yankin silicon. Ƙididdigar ƙididdiga ta nuna cewa yankin silicon da aka yi amfani da shi a cikin gine-gine na 2.5D GPU shine sau 2.5 zuwa 3 na gine-gine na 2.0D na gargajiya. Kamar yadda aka ambata a baya, sai dai idan an shirya kamfanonin kafa don wannan canji, ƙarfin wafer na silicon na iya sake zama mai ƙarfi sosai.

Ƙarfin gaba na kasuwar wafer silicon

Na farko daga cikin dokokin uku na masana'antar semiconductor shine cewa mafi yawan kuɗi yana buƙatar saka hannun jari lokacin da mafi ƙarancin kuɗi yana samuwa. Wannan ya faru ne saboda yanayin yanayin masana'antar, kuma kamfanonin semiconductor suna da wahalar bin wannan doka. Kamar yadda aka nuna a cikin wannan adadi, yawancin masu kera wafer na siliki sun fahimci tasirin wannan canjin kuma sun kusan ninka adadin kuɗin da suke kashewa a cikin kwata-kwata a cikin ƴan kwata-kwata da suka gabata. Duk da mawuyacin yanayin kasuwa, har yanzu haka lamarin yake. Abu mafi ban sha'awa shi ne cewa wannan yanayin ya dade yana faruwa. Kamfanonin wafer na siliki sun yi sa'a ko sun san wani abu da wasu ba sa so. Sarkar samar da semiconductor na'ura ce ta lokaci wacce zata iya hasashen makomar gaba. Makomar ku na iya zama ta wani. Duk da yake ba koyaushe muke samun amsoshi ba, kusan koyaushe muna samun tambayoyi masu dacewa.

Lokacin aikawa: Juni-17-2024